Ultrasonic MEMS Testing

AWG-4000 Series Application Note – Ultrasonic MEMS Testing

Introduction

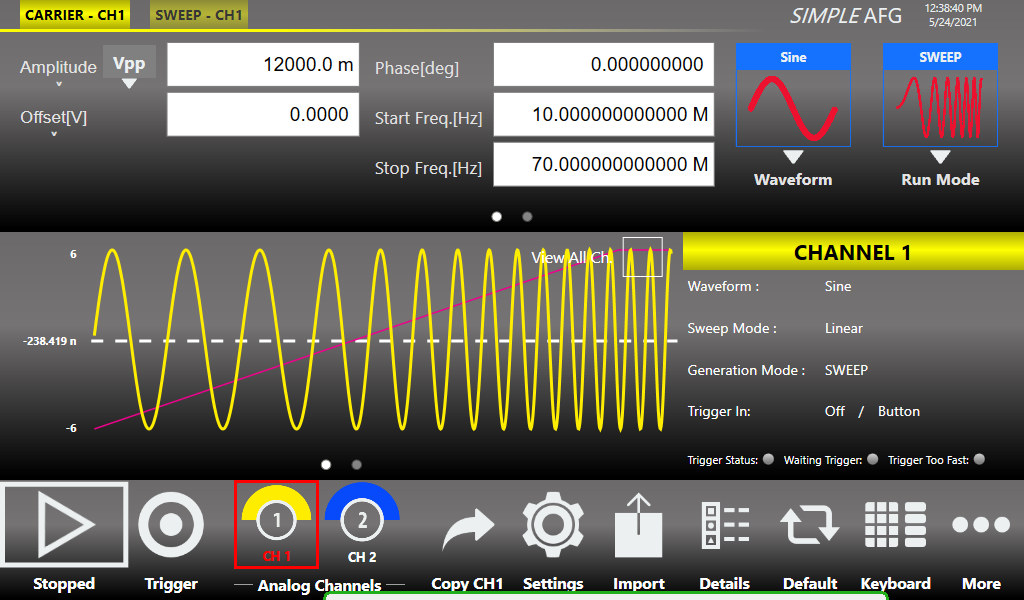

This application note describes how to use the AT-AWG-4000 Series Arbitrary Waveform Generator to generate the signals for the test and the design of Ultrasonic MEMS sensors.

The AT-AWG-4000 Series Arbitrary Waveform Generator simplifies the generation of pulse and chirp signals that are typically used to perform design tests and characterization of MEMS sensors.

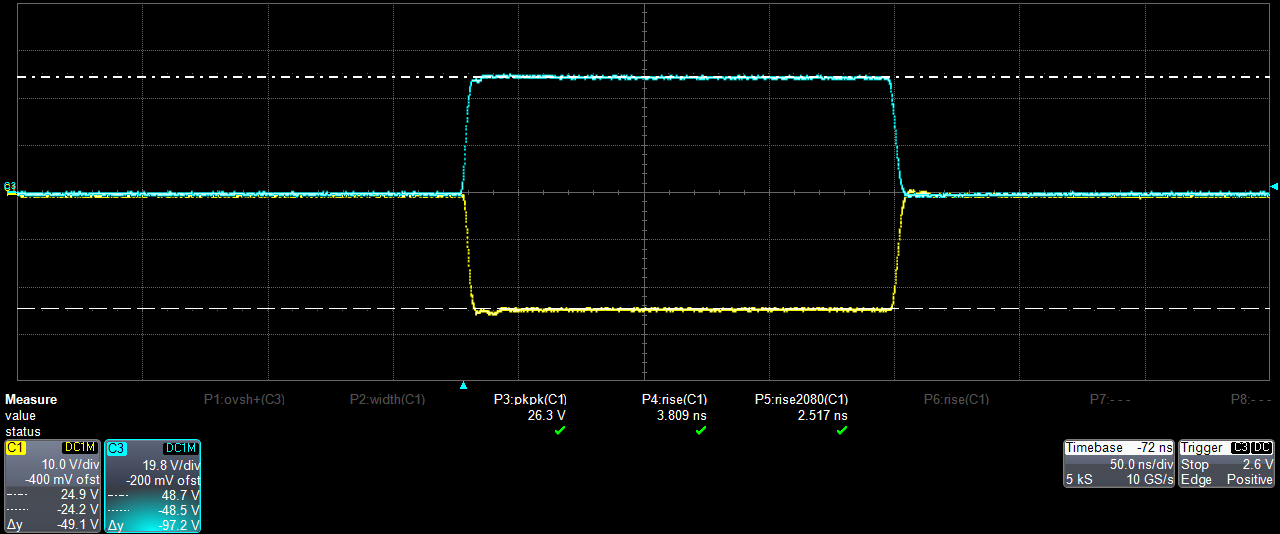

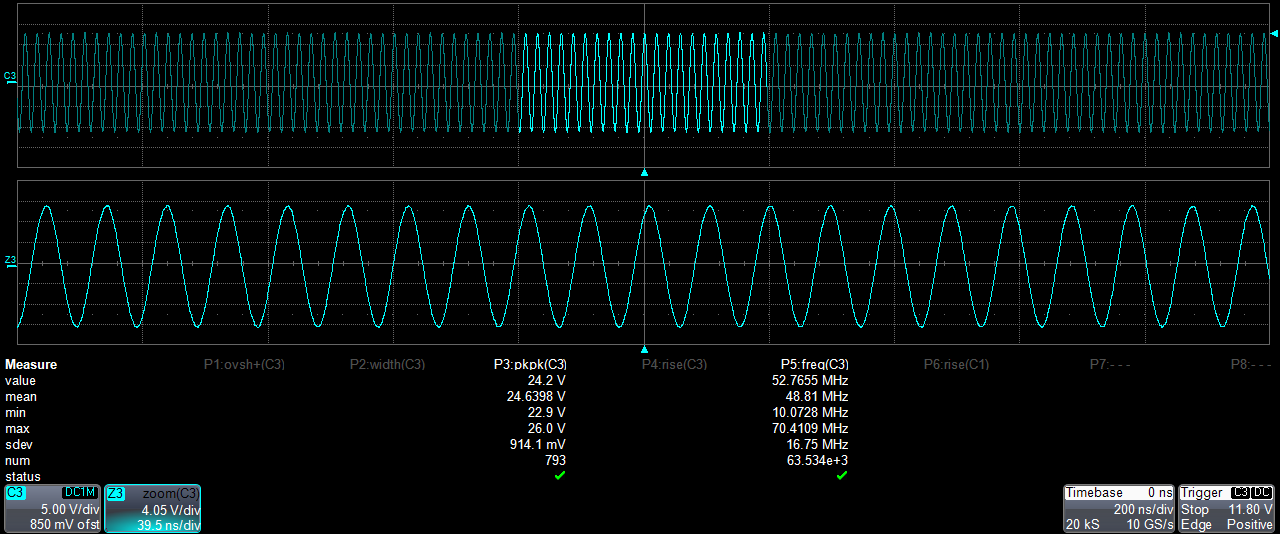

Considering the amplitude of 24 Vpp into High-Impedance (12 Vpp into 50 Ohm) joined to an analog shift of ±12V into High-Impedance, the AWG-4000 represents the ideal solution for these kind of tests where high voltage amplitude, programmable pulse’s width and rise/fall time are mandatory.

General considerations about MEMS Sensors

MEMS (Micro-Electro-Mechanical systems) sensors leverage silicon’s unique mechanical properties to integrate mechanical structures able to sense acceleration, rotation, angular rate, vibration, displacement, heading, and other physical and environmental properties.

Those considerations united to an analog front end with an excellent harmonic distortion, produce a circuit that combines electrical circuits and 3-dimensional mechanical structures.

Nowadays MEMS sensors and microphones are widely used in many applications starting from the distance and motion detection, mobile, IoT, drones, automotive, pressure measurement, humidity and temperature sensing to just name a few.

Main types of MEMS Sensors

Ultrasonic sensors for distance measurement

To reduce the spread of COVID-19, offices and factories are being required to create an environment in which social distancing between workers and safe work practices are ensured.

Distance measurement is as accurate as less than 1cm for ultrasonic sensors and less than 10cm for UWB, compared to as much as several meters for BLE, which is not enough to detect two people as they approach the recommended safe distance of approximately 2m.

The ultrasonic transducer mounted on the sensor transmits an ultrasonic pulse and receives a wave reflected back from the object. Using this Time-of-Flight (ToF), the distance from the object can be accurately detected.

Ultrasonic MEMS for Industrial and Automotive Applications

Industrial applications include precision agriculture, construction machinery, drones, automatic guided vehicles (AGVs), robots and industrial motors.

Motion sensor data has become critical in enabling automation, improving efficiency, and monitoring conditions in these industrial applications.

MEMS accelerometers products delivers the precise motion, vibration and inclination measurements that these applications need. About automotive, the MEMS sensors can be used for a wide range of applications starting from dead reckoning, vehicle to vehicle location, vision systems, augmented reality, lift gate control, telematics to In-vehicle Infotainment and smart antenna.

MEMS Barometric Pressure Sensors

Latest barometric pressure sensors use an innovative capacitive MEMS architecture to deliver lower power consumption and lower noise than competing technologies.

These kind of MEMS can measure height change as small as 5 cm, less than the height of a single stair step and they are best suited for smart phones, tablets, wearables, drones, and many other devices to determine accurate location of emergency calls, track changes in elevation for activity monitoring, support indoor or 3D navigation, and other motion- or position-based services.

Signal Generation for MEMS

Ultrasound Medical Imaging Applications

The ultrasound imaging has gained much interest in the medical field due to its less-harmful characteristic to the human body in comparison with other well-known methods such as magnetic resonance imaging, computed tomography, and X-rays.

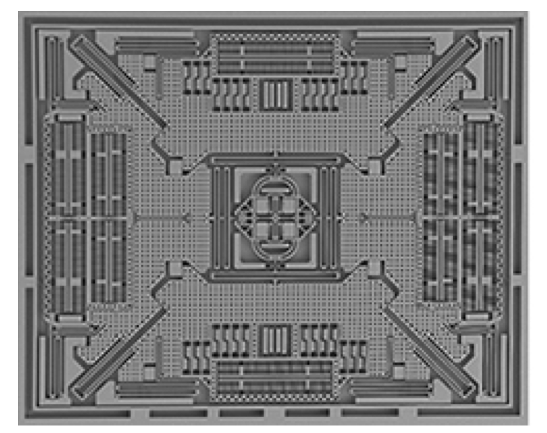

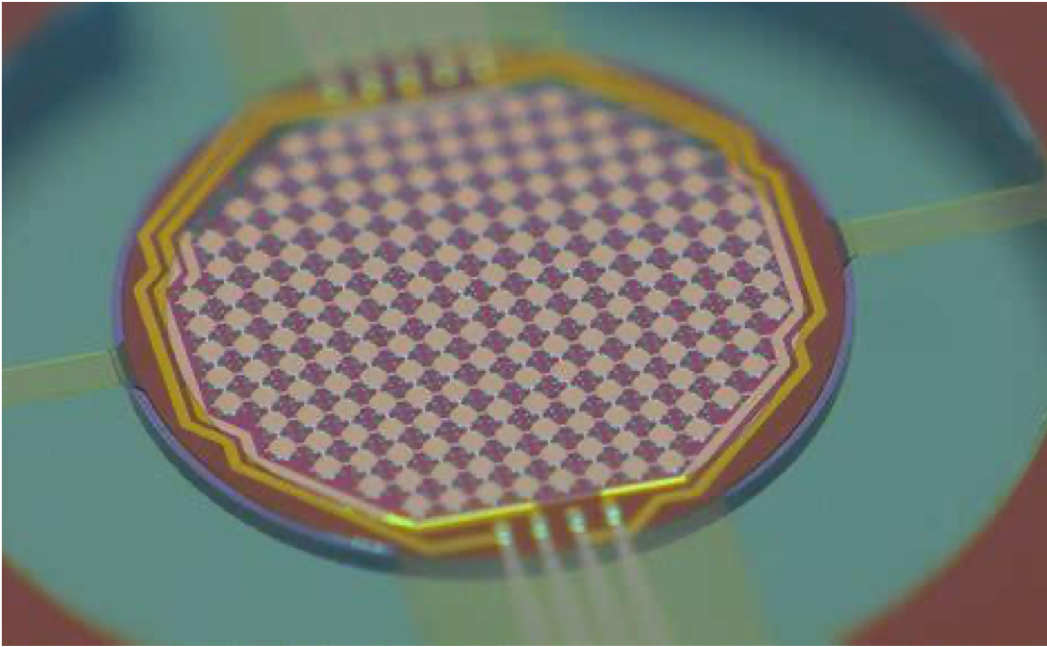

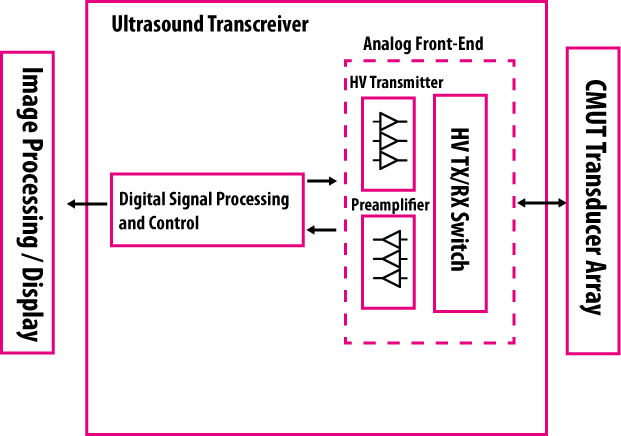

In addition, the emergence of the capacitive micromachined ultrasound transducer (CMUT) device technology during the last decade has propelled the interest even further. In comparison with its piezoelectric counterpart, the CMUT provides the advantages of wider operational bandwidth, simpler fabrication for large array implementations

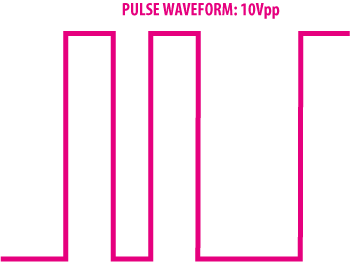

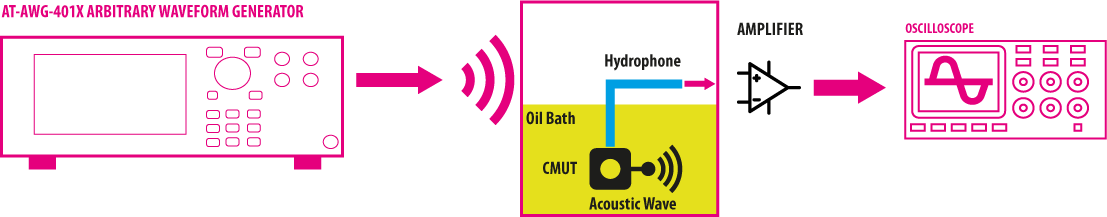

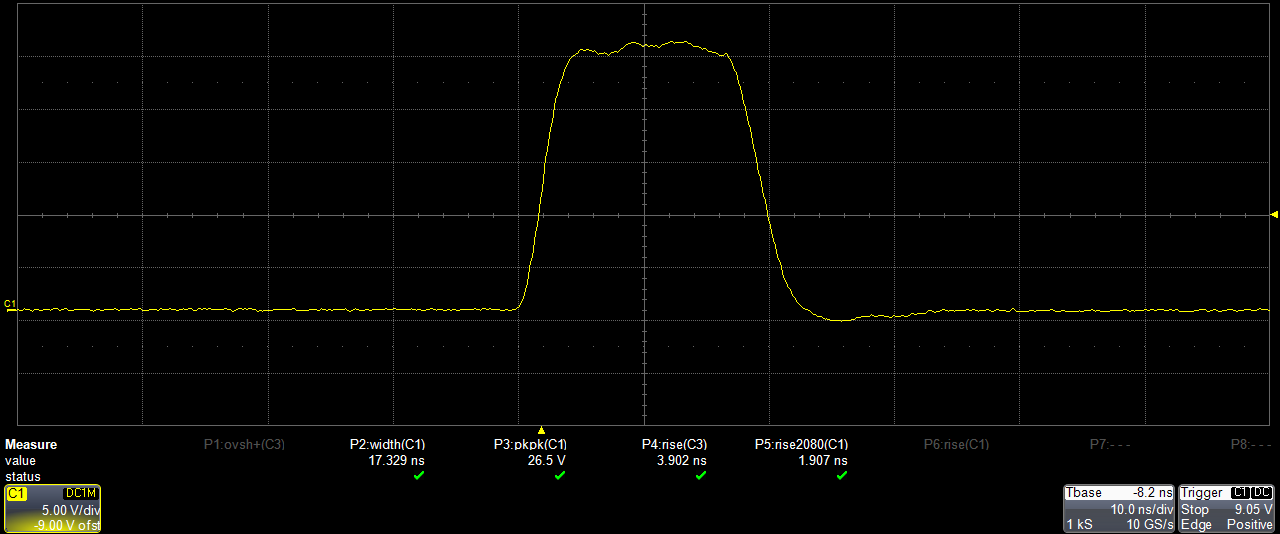

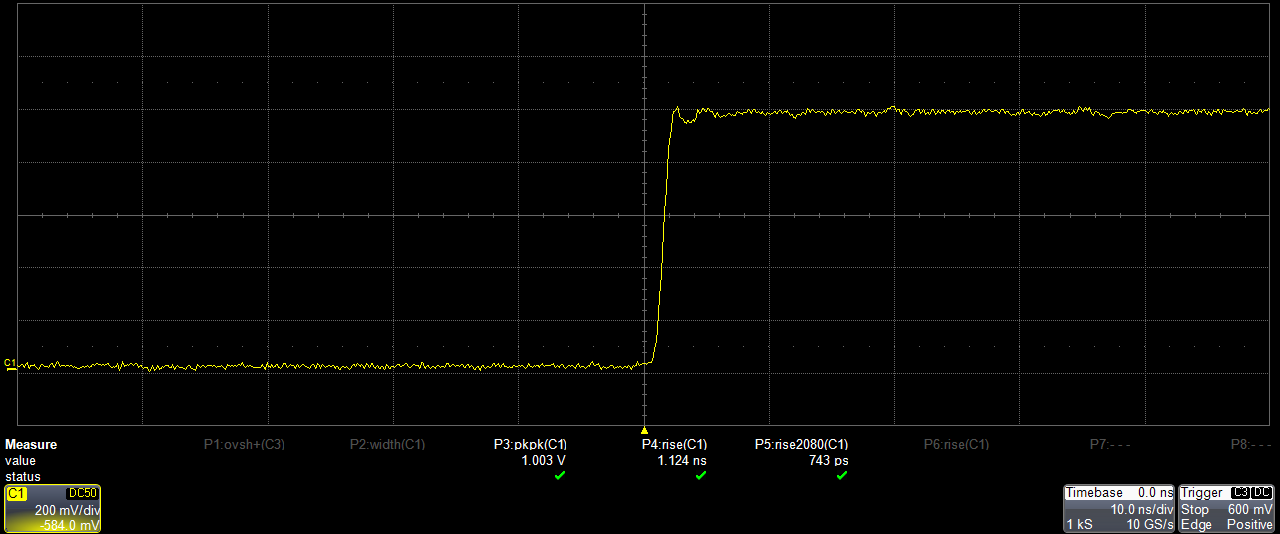

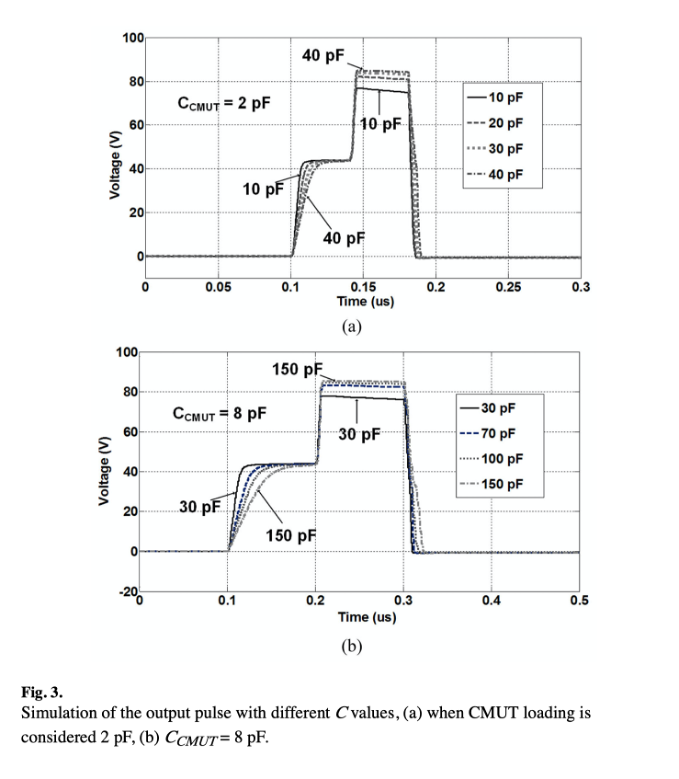

The HV output pulse driver and the level shifter adopts a multiple-stacked architecture with dynamic gate biasing circuit in order to generate over 10 Vpp pulse signal at 1.25-MHz frequency while driving the CMUT device immersed in an oil environment.

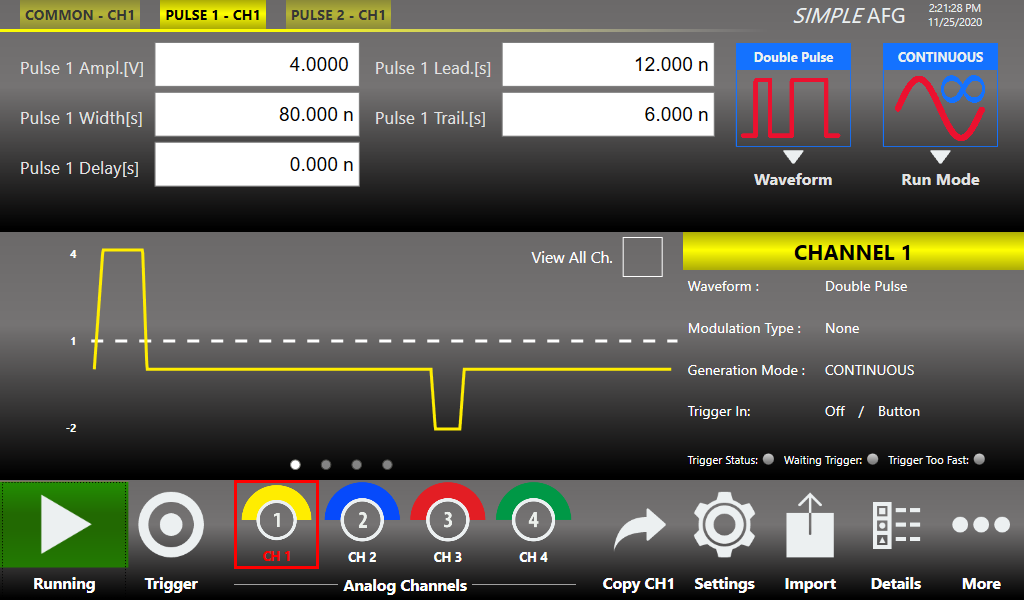

The pulsewidth, the period, and the required amount of generated acoustic pressure, which relates to the maximum voltage of the output pulse signal, are decided in the system level depending on the specific medical imaging application, as well as the device characteristics of the following transducer.

The CMUT-mounted PCB is placed in a glass container filled with vegetable oil to mimic underwater environment, while the IC mounted board is placed outside.

A hydrophone is placed at a close distance of a few millimeters from the CMUT to measure the resulting transmitted acoustic pressure and convert to a voltage signal.

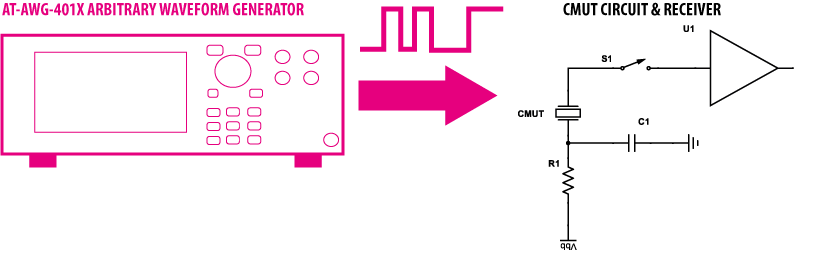

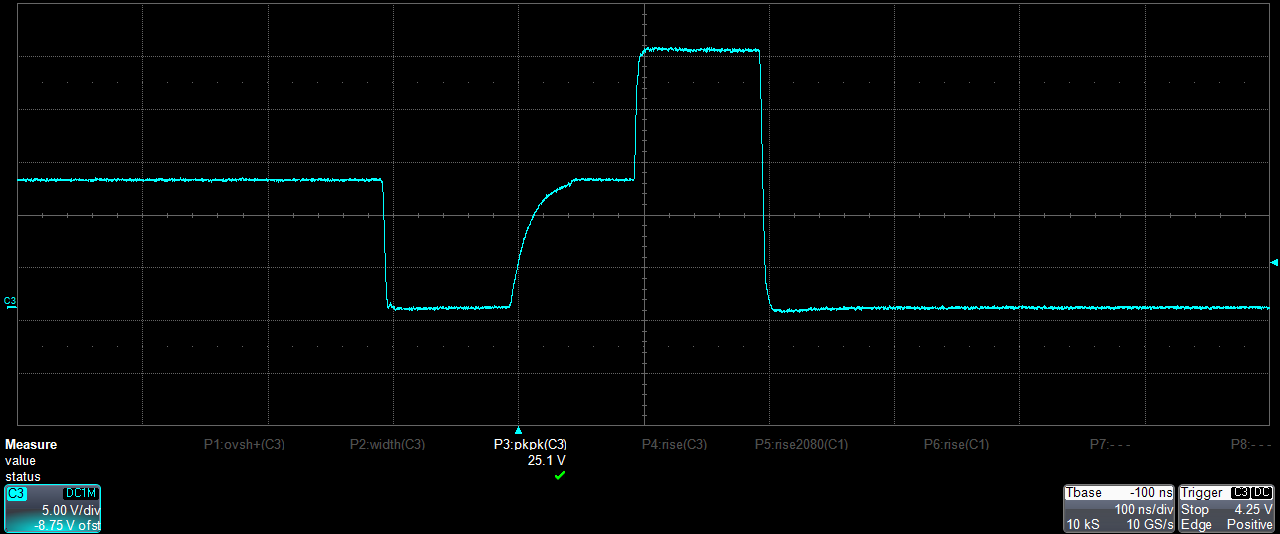

During the design stage, usually an external arbitrary waveform generator is needed to generate an input pulse of 10Vpp to drive the CMUT at the output.

A specific medical imaging application needs signals with different amplitude levels: the CMUT converts the electrical signal to an acoustic pressure signal corresponding to the amount of applied voltage.

The Active Technologies AWG-4000 generators have unmatched voltage swing capability combined with an hardware offset feature: the 12 V pp (50 Ω into 50 Ω) amplitude range and the ±6 V (50 Ω into 50 Ω) hardware offset voltage offer a total voltage window of 24Vpp into 50 Ω or 48Vpp into High-Impedance.

Multi-Level Pulse for Medical Imaging Applications

A two levels or three level pulse is presented for medical ultrasound imaging applications, particularly those that use capacitive micromachined ultrasonic transducers (CMUT).

The pulser employs a bootstrap circuit combined with dynamically-biased stacked transistors, which allow HV operation above process limit without lowering device reliability.

Medical ultrasound imaging has had a significant impact on clinical practice by providing real-time images of different organs with high spatiotemporal resolution non-invasively at low cost. In recent years, the capacitive micromachined ultrasound transducers (CMUT) have shown several advantages over the conventional bulk piezoelectric transducers, due to smaller size, wider bandwidth, and ease of integration with interfacing circuitry. Compared to piezoelectric transducers, CMUTs typically have larger electrical impedances for the same transducer area.

Ultrasound pulse generator is one of the key building blocks of medical ultrasound imaging systems, which drives the ultrasound transducers, including CMUTs with high voltage (HV) output swing to create an ultrasonic pressure pulse towards the target tissue.

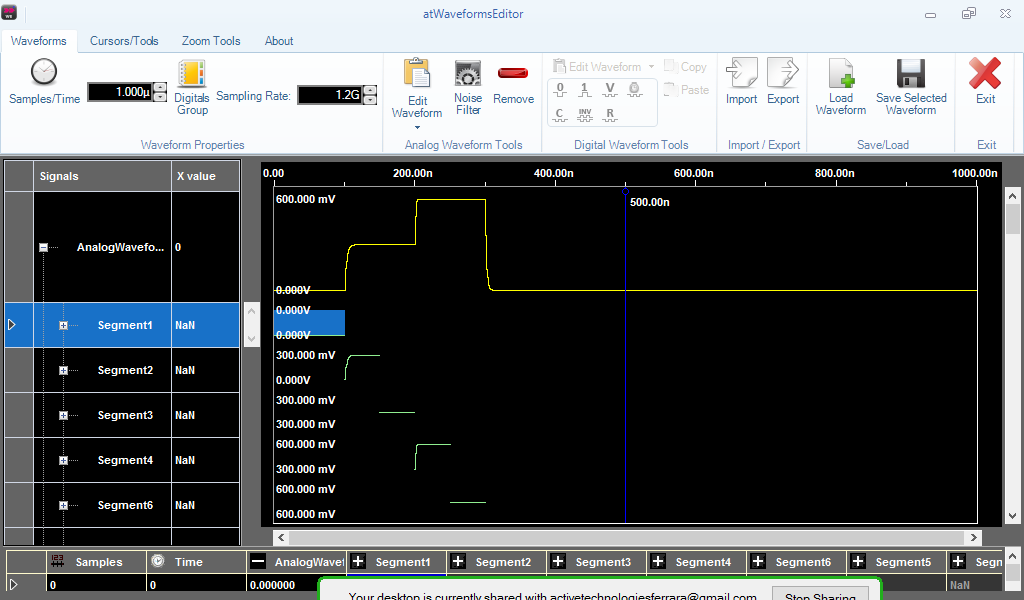

The Active Technologies Waveform Editor tool, allows you to easily create multi-level pulses that are a key-factor of this kind of application. It is also possible to add noise and/or filters to simulate a real-life environment.

Security of Ultrasonic Sensors for Autonomous Vehicles

Automobile is one of the most promising sectors for the Internet of Things (IoT). Self-driving technologies are built on modern sensors that enable vehicles to monitor the driving environment by themselves.

The safety of self-driving vehicles is determined by the reliability of sensors.

They are widely used on IoT devices for ranging and occupancy detection, which correspond to two scenarios on a vehicle:

- parking when a car is traveling at low speeds

- detecting blind spot at high speeds.

Sensors should detect all present obstacles and avoid false alarms and vehicles should handle the following two scenarios correctly.

- Stop With Obstacles: a vehicle should stop moving toward obstacles on the driving path, and avoid active collision.

- Keep Moving Without Obstacles: a vehicle should keep moving when there is no obstacle on the driving path, and prevent passive collision with the unprepared traffic.

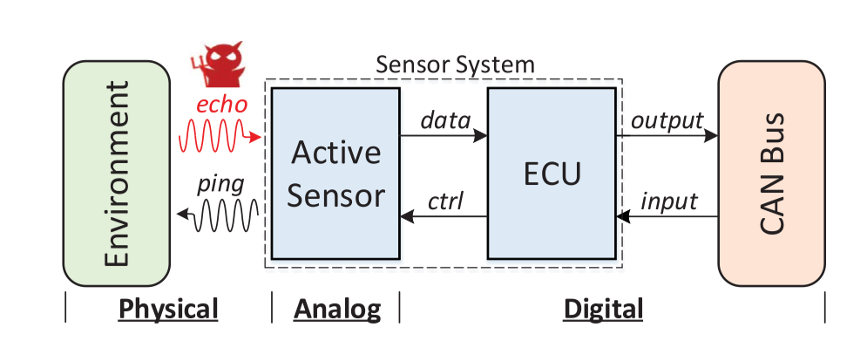

During the design stage, it is possible to simulate the attacks on stand-alone ultrasonic sensors in the laboratory and the onboard sensors of several vehicles outdoors.

Transmitting over-the-air signals created using an Arbitrary Waveform Generator, it is possible to create different attacking scenarios to simulate the following situations:

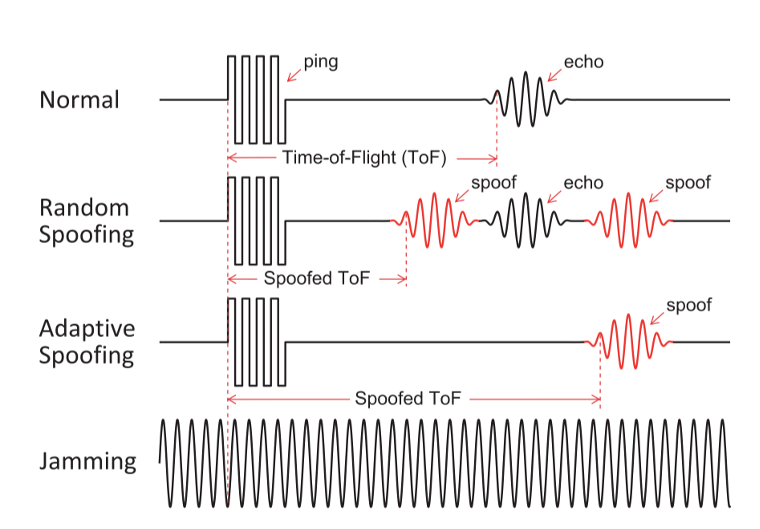

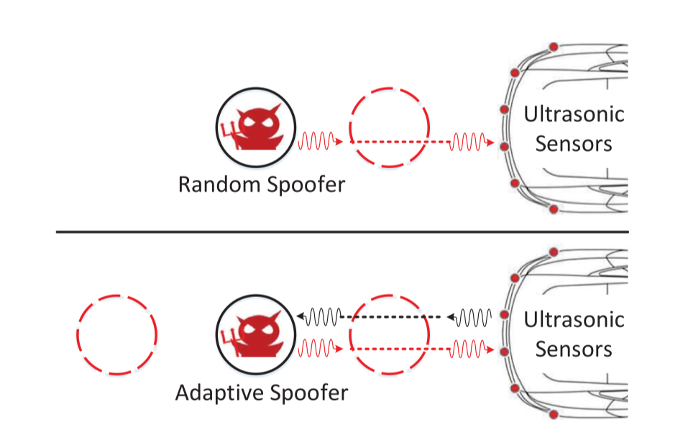

- A Vehicle Stops When It Should Keep Moving: we trick the on-board ultrasonic sensors to report non-existing obstacles anywhere within the detection range by designing two types of spoofing attacks—random spoofing and adaptive spoofing.

- A Vehicle Keeps Moving When It Should Stop: the design choices of ultrasonic sensors make it possible to hide obstacles. A jamming attack or an adaptive spoofing attack can both prevent sensors from reporting an obstacle on the road.

Ultrasonic sensors were first introduced to automobiles as sensors of parking assistance systems in the early 1990s.

Attack Scenario: the adversary can eavesdrop on the physical signals from on-board sensors, and actively generate forged echoes in an arbitrary form (frequency, amplitude, duration, phase, etc.), thereby corrupting or overpowering other concurrent physical signals in propagation.

Security of Ultrasonic Sensors for Autonomous Vehicles

- Spoofing Attacks: Spoofing attacks involve emitting carefully crafted signals (e.g., ultrasound pulses) that are identical to those transmitted by the sensors, i.e., with the same frequency, modulation, etc.

As a result, the sensors may interpret the spoofing signals the same way as the authentic signals, and falsely detect non-existing obstacles. By carefully adjusting the timing of the spoofing signals, an adversary may “create” fake obstacles at various locations of her choice. - Jamming Attacks: Jamming attacks involve injecting similar but stronger signals to overpower the real ones. Sensors are typically designed to be robust against benign ambient noises, but they hardly expect strong interference. It is unclear whether sensors can detect objects in the presence of jamming attacks. In case the interference is so strong that it causes sensor denial-of-service, it is also unclear whether sensors and automobiles will fail gracefully and do not cause fatal accidents.

Building a Random Spoofer: to validate spoofing attacks, we acquired ultrasonic transducers whose working frequencies are the same as the ones of the target sensors.

To drive the transducers, we utilize an off.the-shelf hardware that can be an Awrbitrary Waveform Generator.

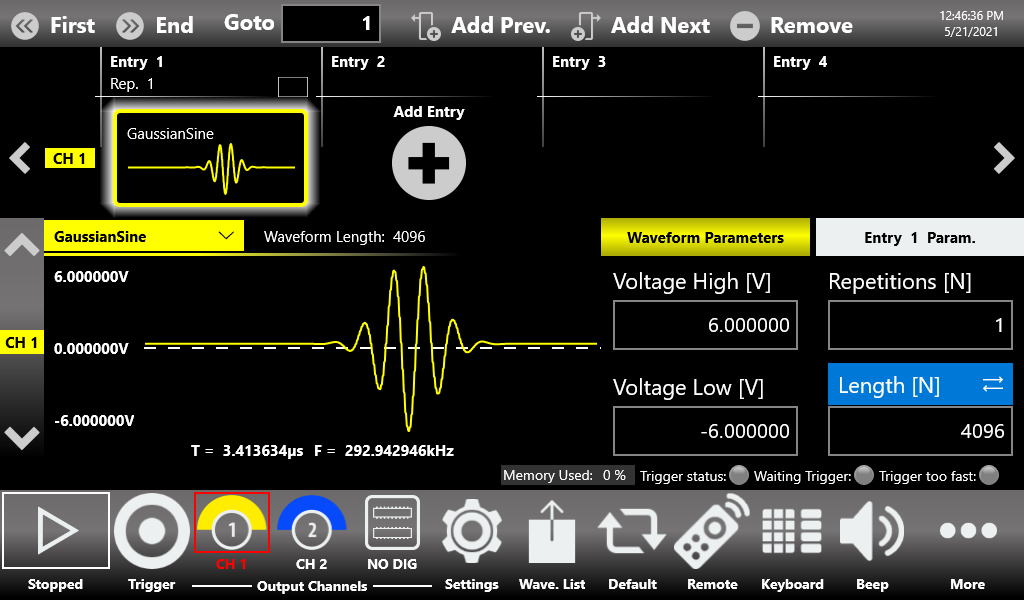

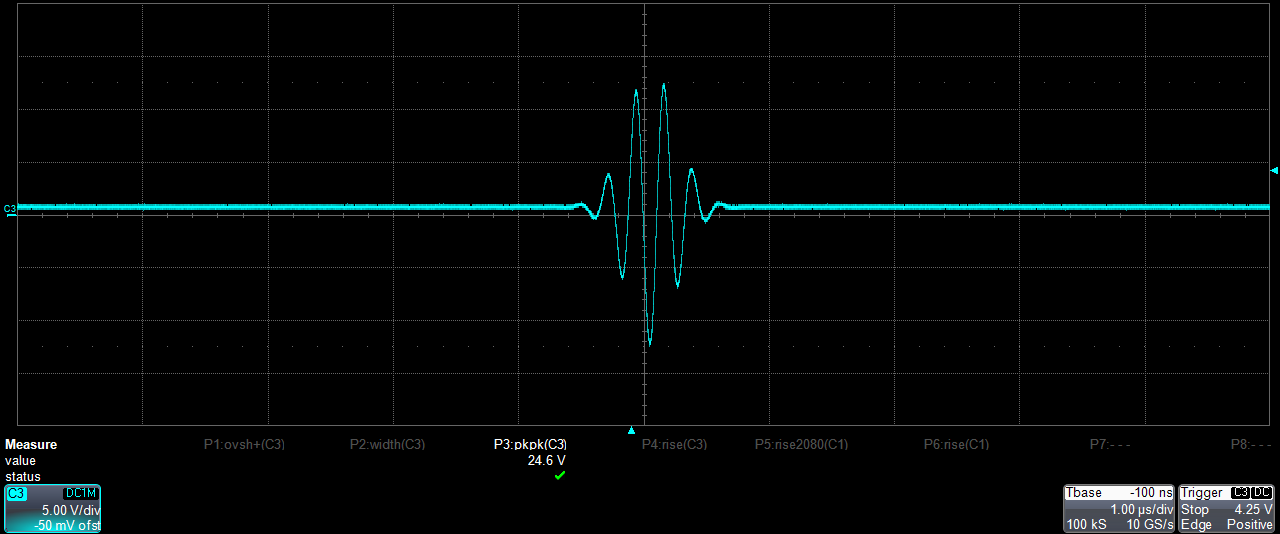

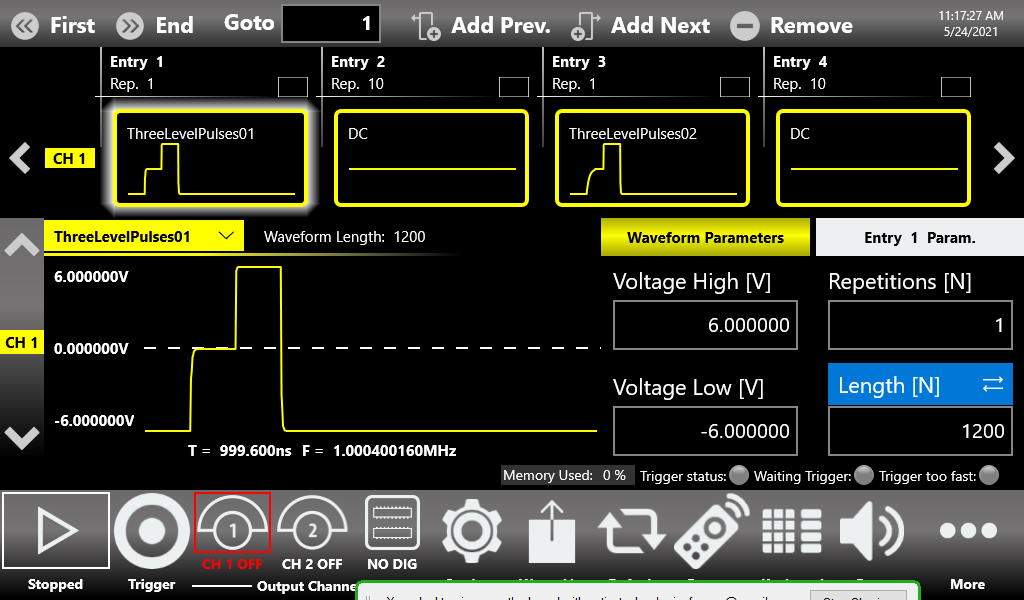

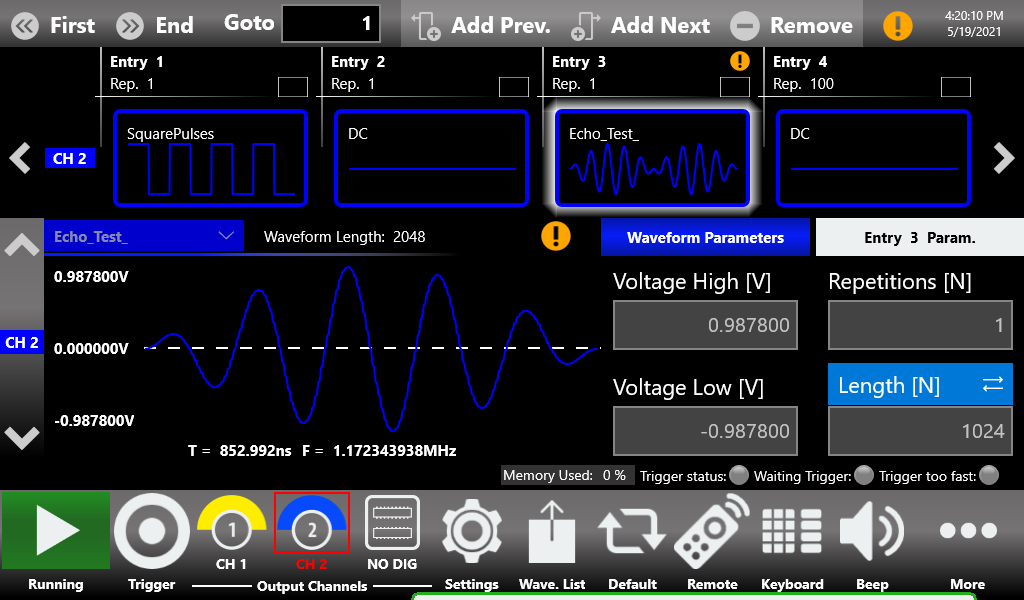

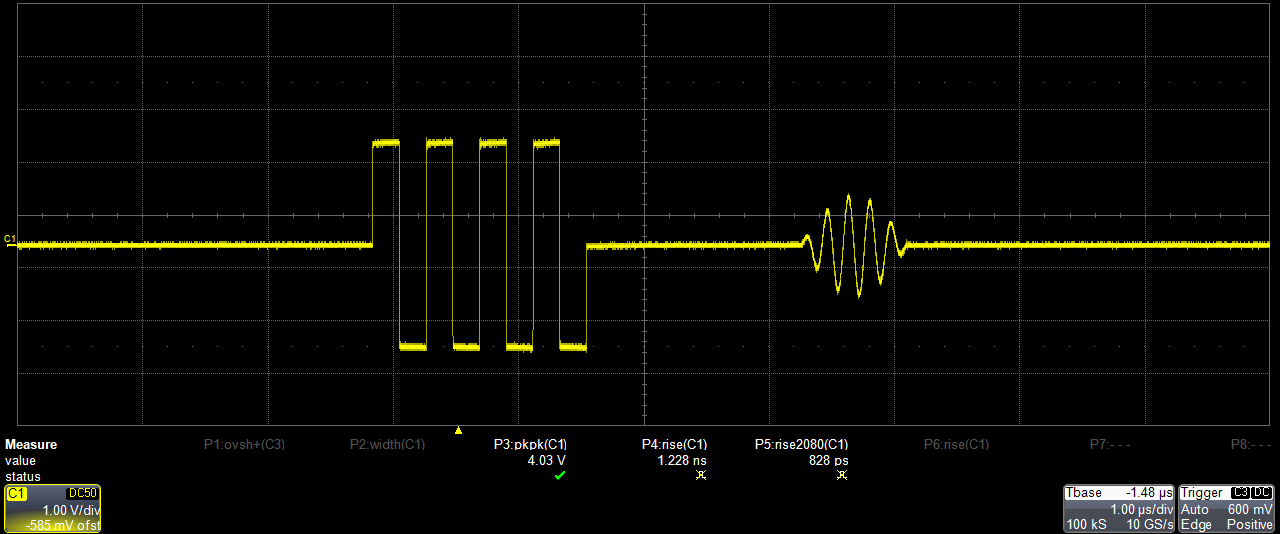

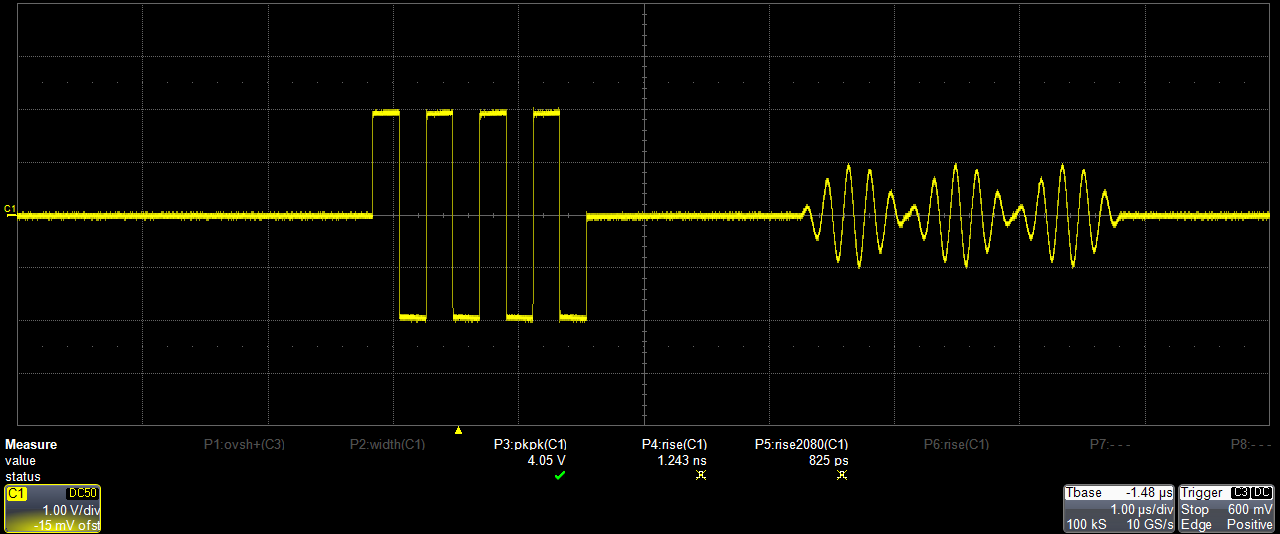

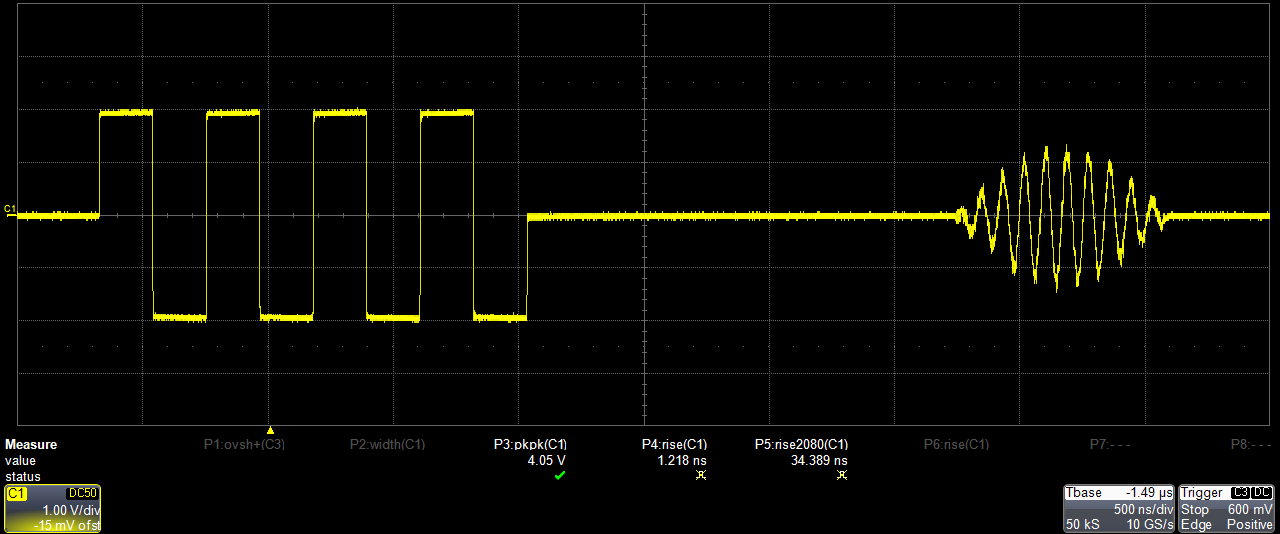

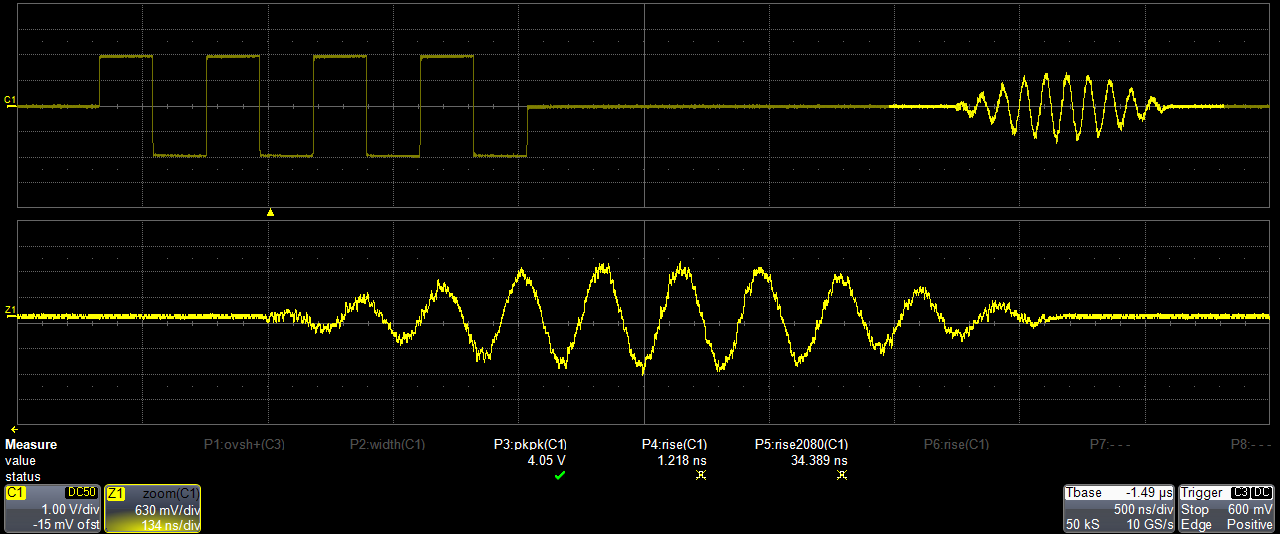

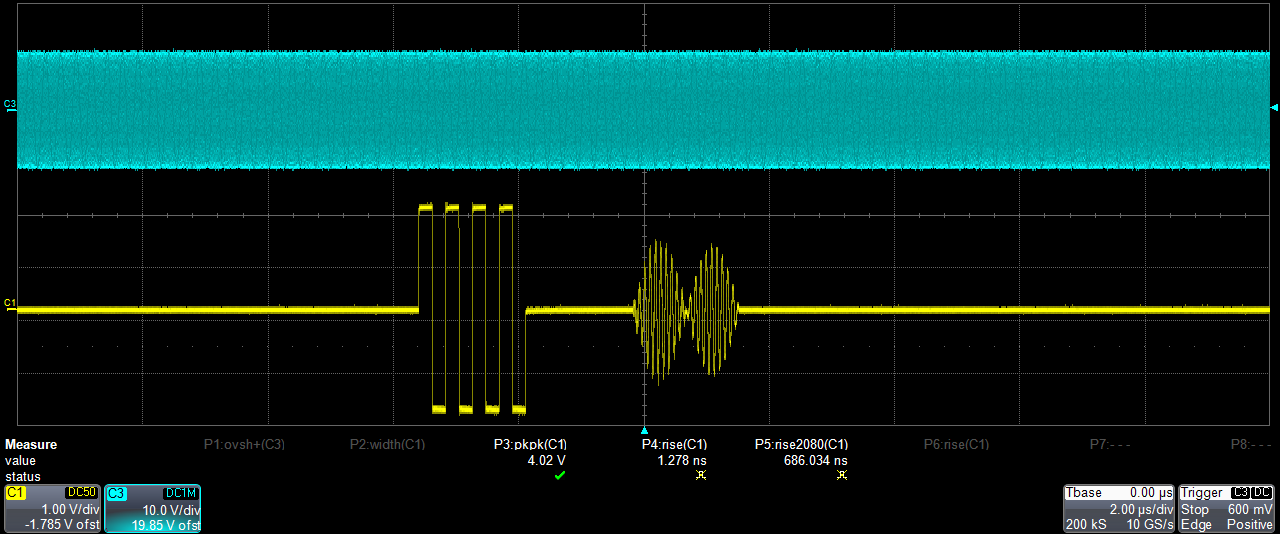

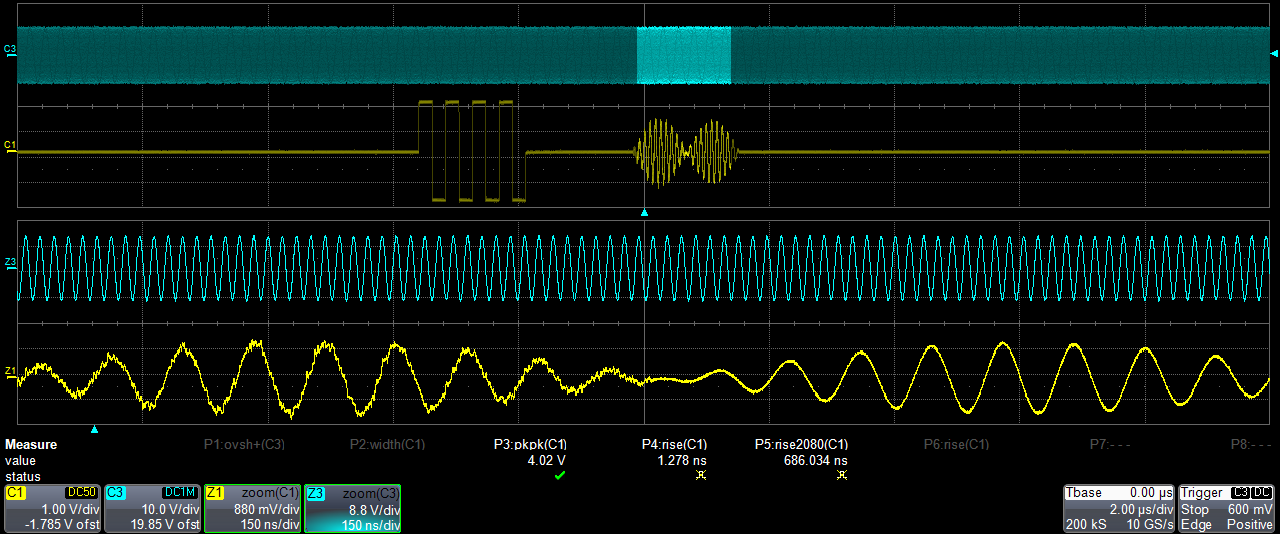

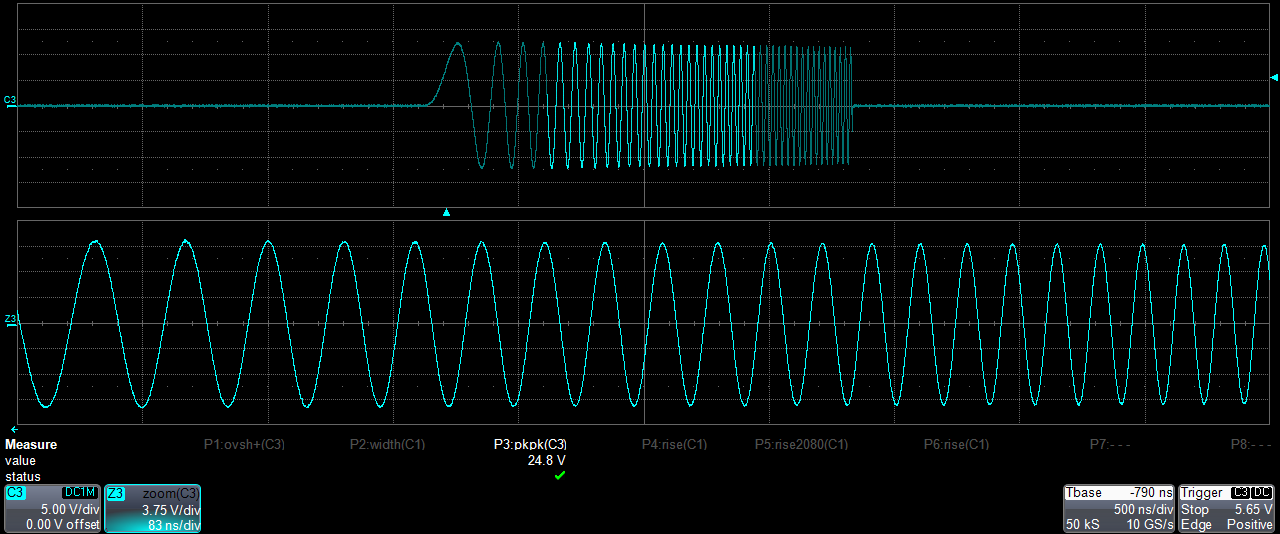

The picture below represents the sequencer of the AWG-4000 Series that has been loaded with a train of pulses, a DC-level that acts as a pause and an echo that is the response of the ultrasound

The AWG-4000 has a built-in Gaussian random noise generator that can add noise to your signal to emulate the response of the ultrasound sensor in a noisy environment or to simulate the interaction between the returning signals and the environment.

The Waveform Editor software package allows you to create in an easy-way very complex analog and digital waveforms; moreover it is possible to add noise & filter features to the signal that you are editing.

Jamming Attacks

Jamming attacks generate ultrasonic noises that induce continuous vibration on the sensor membrane, and render distance measurement impossible.

Voltage Level: the amplitudes of sounds created by piezoelectric crystals rely on the voltage level of the signals that drive the crystals. Thus, the effective jamming distance is determined by the applied voltages.

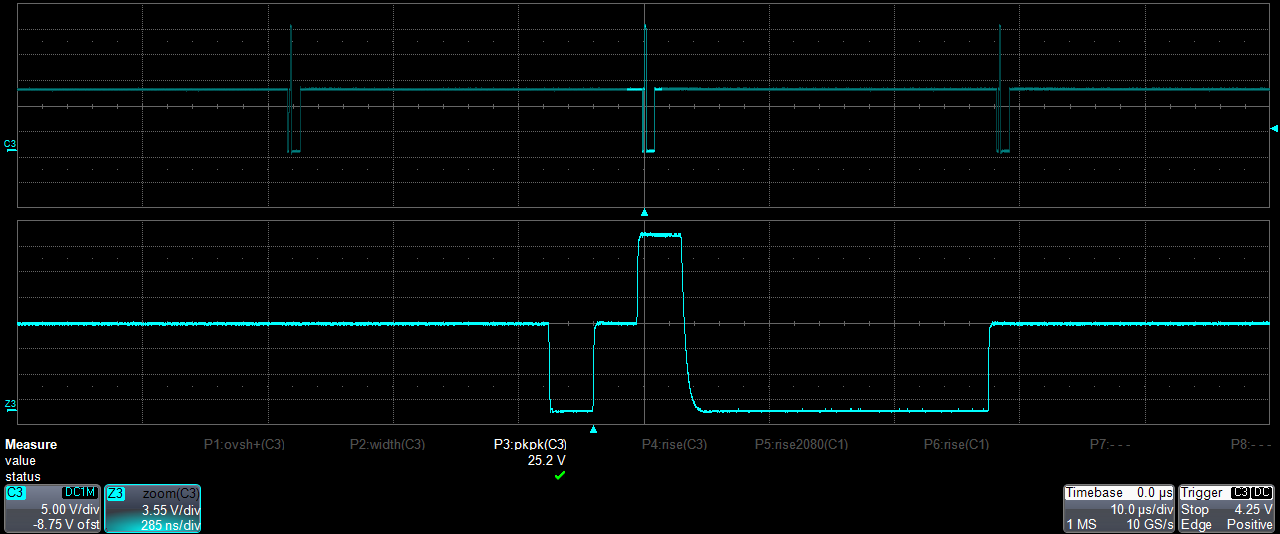

The AWG-4000 Arbitrary Waveform Generator is able to generate square pulse up to 24 Volts into High-Impedance.

Ultrasound Communication and Range Finder Systems for Sensors

Ultrasonic time-of-flight (ToF) sensors are commonly recognized as the best range-sensors for automotive and industrial applications — as well as for drones and robotics. They offer numerous advantages over optical or infrared sensors. They deliver the most accurate range measurement regardless of target size or color, are immune to ambient noise, and they work in direct sunlight.

For these reasons and because they are robust, accurate and reliable, ultrasonic sensors are widely used in industrial and automotive applications

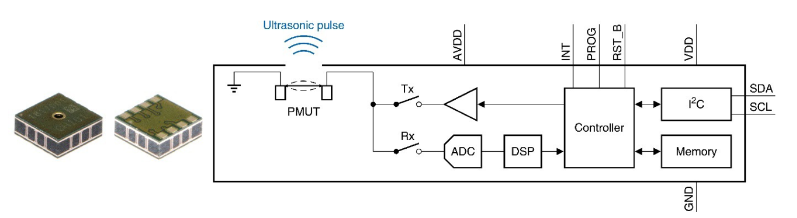

MEMS-based ultrasonic sensors that offer the same performance and reliability as conventional ultrasonic sensors but with a form-factor up to 1000 times smaller and a power consumption up to 100 times lower than that of conventional ultrasonic sensors. The miniature sensors are small enough to enable the entire spectrum of ultrasonic sensing in compact consumer applications such as smartphones and wearables.

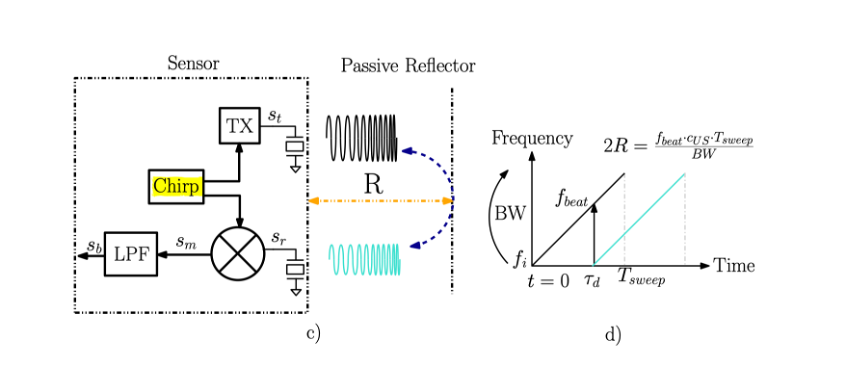

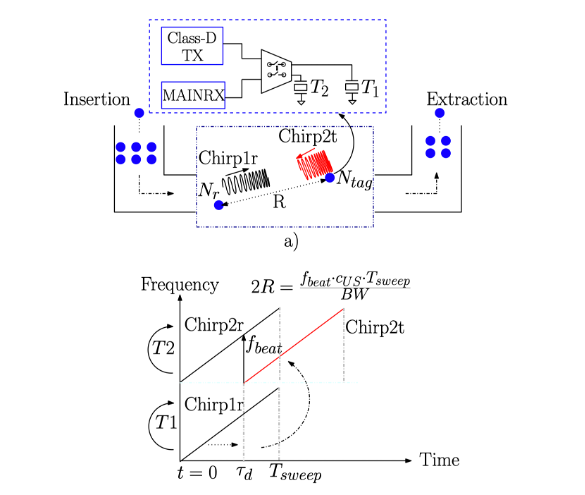

The sensor measures range by emitting an ultrasonic “chirp” and then listening for echoes returning from targets in the sensor’s field-of-view. Each echo travels at the speed of sound, and an echo’s time of flight provides a precise measure of the distance to a corresponding target.

Instead of transmitting the signal with a linearly increasing frequency in time, a chirp that has a sawtooth (up and down) frequency change in time should be used for estimating the relative distance and the velocity of the nodes.

The conventional FMCW method uses the echoes reflected from objects in the environment and provides a distance measurement method for these objects. This method could be adopted for distance measurement in the go-with-the-flow approach. In this case, each node in a swarm would perform the distance measurement independent from each other. Thus, no synchronization would be needed.

Ultrasound MEMS for Damage Detection in Concrete

Nonlinear ultrasonic techniques have been developed over the last decades to detect the presence of damage in materials of interest in the field of civil engineering, such as concrete or mortar.

High-resolution ultrasound waveform generation combined with high voltage signals allow to detect the small variations in the sample microstructure and are therefore more adapted to detect the presence of small cracks or damaged areas with respect to traditional linear ultrasonic techniques.

Slow Dynamics

The excitation was applied to one end of the sample using the AWG-4000 Arbitrary Waveform Generator. The response temporal signal was detected at the other end using a digital oscilloscope for data acquisition. Signals were recorded in a short time window once stationary conditions were reached.

Fast Dynamics

The same sample and experimental set-up was also used to consider fast dynamics effects. In this case, the protocol for the source amplitude variation was different.

The signal amplitude at the edge is proportional to the strain amplitude in the sample, since we are exciting compressional waves. Results show softening of the material and increase of attenuation with increasing strain, in agreement with observations in the literature for similar samples.

Conclusions

Ultrasonic MEMS sensor can address a wide range of applications and they are becoming very popular these days.

Semiconductor and digital imaging companies are investing money and research time into this particular market segment; the market forecast is about 6 Billion USD in 2025.

The AWG-4000 Arbitrary Waveform Generator Series represents a key-component for the design, test and characterization of next generation Ultrasonic MEMS and components.